HK55-F-C Cast Iron Pneumatic Actuator Fluorine Ball Valve

Price: Contact

Product code: HK55-F-C

HK55-F-C Cast Iron Pneumatic Actuator Fluorine Ball Valve

The series of corrosion-resistant fluorine lined ball valve is designed for the opening and closing control of various strong corrosive medium pipelines. Flange type fluorine lined ball valve cavity and ball are lined with corrosion-resistant and aging resistant polypropylene by high-pressure injection molding process, so it has reliable corrosion resistance and sealing performance. It is widely used in chemical, petroleum, metallurgy, medicine and other industrial sectors to adjust or cut off the strong corrosive medium such as acid and alkali in the production process, and has the most obvious effect in the control of water treatment process. It is one of the most ideal choice of anticorrosive valve equipment at present

- Model: HK55-F-C

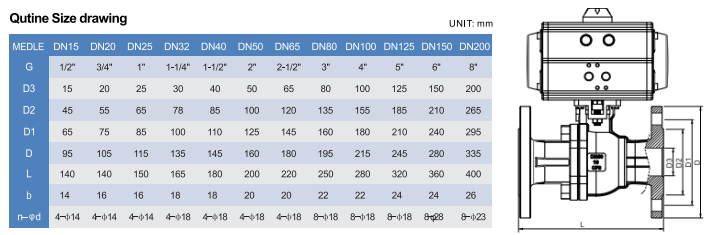

- Size Range: 1/2" to 2"

- Pressure Range: 1.6MPa to 6.4MPa

- Material: Cast Iron

–

+

Order

Product information

Flange Fluorine Lined Ball Valve with pneumatic actuator

- It is compact and reliable, easy to operate

- Simple structure, convenient maintenance

- The actuator is hard oxidized for longer service life

- Bidirectional sealing, any flow direction of medium

- Good corrosion resistance and sealing performance

- It is a new type of valve with automatic control and operated remotely and intelligently

![]()

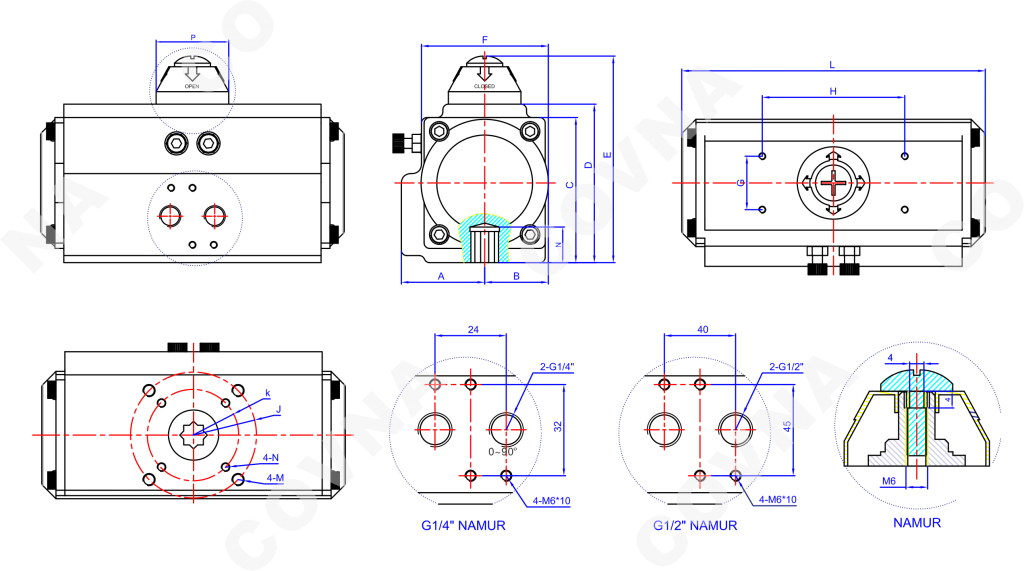

| Structure | Rack and pinion pneumatic valve actuator |

| Mounting | ISO5211, NAMUR, DIN3337 |

| Air Supply Pressure | 2.5 to 8 bar |

| Double Acting Type | Air to open, air to close, air supply failure to keep the current position. Torque range from 8Nm to 4678Nm |

| Single Acting (Spring Return) | Air to open, interrupt air to close, air failure to close. Torque range from 5Nm to 2792Nm |

| Optional Accessory | Positioner, Litmit Switch, F.R.L, Pneumatic Solenoid Valve, Gearbox |

![]()

| Body | Valve components | ||

| Size range | DN15~DN100 | Sealing material | PTFE, PPL |

| Body material | Cast Iron | Core material | Stainless steel |

| End conection | Flange | Stem material | Stainless steel |

| Operating pressure | 1.6, 2.5, 4.0, 6.4MPa | Applicable media | Water, oil, Gas, Liquid, steam, powder, anti-corrosive base |

| Structure | Floating ball core | ||