HK60-Z-JS Stainless Steel Multi-turn Actuator Globe Control Valve

Price: Contact

Product code: HK60-Z-JS

HK60-Z-JS Stainless Steel Multi-turn Actuator Globe Control Valve

Globe valves are ideal for throttling service. Their flow characteristics permit accurate and repeatable flow control. Stainless steel 316 globe valve has a bolted bonnet, non-rising stem, and flanged connections on both ends, and is used to control flow (throttling) in a pipeline or water plumbing system.

The valve body is constructed of stainless steel 316 for higher strength and greater corrosion resistance. The valve has a bolted bonnet for tight assembly and reduced risk of leakage, and flanged end connections for bolting to compatible pipe flanges. The stem/wedge connection meets the API 600 Pull test.

- Model: HK60-Z-JS

- Size Range: 2'' to 16''

- Pressure Range: 0.6MPa~2.5MPa

- Material: Stainless Steel

–

+

Order

Product information

SS316 Motorized Actuator Flange Globe Valve

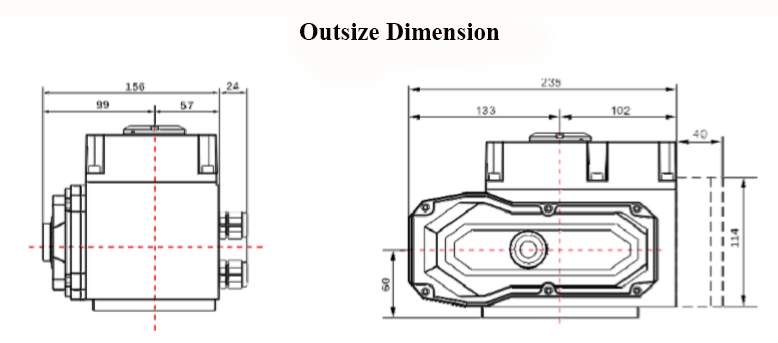

- Exquisite and small, beautiful and generous, unique internal design, tough and wear-resistant, not easy to damage

- Elegant appearance: die cast aluminum alloy shell, fine and smooth appearance, and can reduce electromagnetic

- Generous function: switch type, passive contact type, proportion type, intelligent adjustment type

- Precise wear resistance: perfect combination of worm wheel and worm, harmonious linkage

- The integration of worm gear output effectively reduces the connection gap and greatly improves the transmission accuracy

- Safety guarantee: through ac1500v voltage withstand test, H-class highly insulated motor, Guarantee the safety of machine body and production

- Simple matching: single-phase, three-phase, DC power supply, simple external line

![]()

| Power supply | conventional: single phase 220v, three phase 380v |

| special: three phase 400v, 415v, 660v(50Hz, 60Hz) | |

| Working environment | Ambient temperature: -20 ~ + 60 ℃ (special temperature environment can be customized) |

| Relative humidity: 95% (at 25 ° C) | |

| Protection level | Outdoor type and explosion-proof type are IP55 (IP65, IP67, IP68 can be provided for special order) |

| Working system | short time 10 minutes (15-60 minutes for special order) |

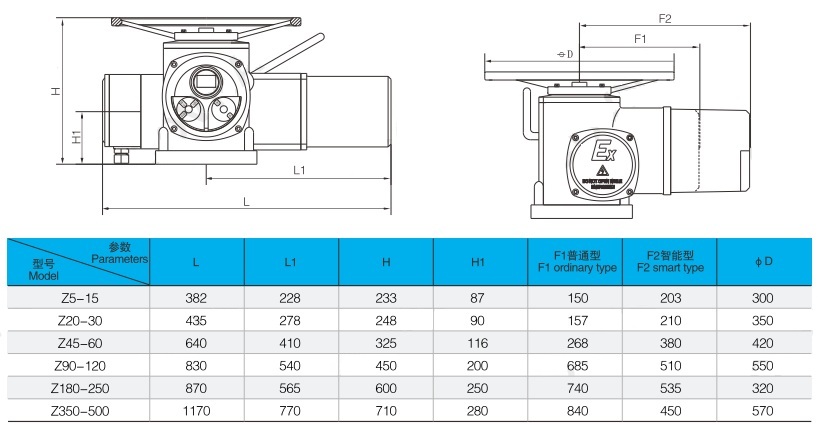

![]()

| Valve Body | Valve components | ||

| Nominal size | DN50-DN400 | Sealing material | Stainless Steel |

| Body Material | Cast Iron, WCB, Stainless Steel | Disc Material | SS304 |

| End Connection | Flange | Stem Material | Stainless Steel |

| Operating Pressure | 1.0 / 1.6 / 2.0 / 2.5 MPa | Applicable media | Water, Air, Gas, Oil, Liquid |

| Structure | Midline structure/A-Type | Design standard | ANSI, JIS, DIN, BS, GB |